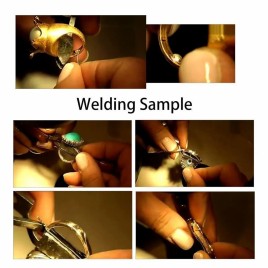

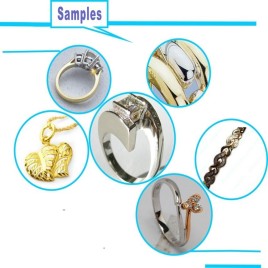

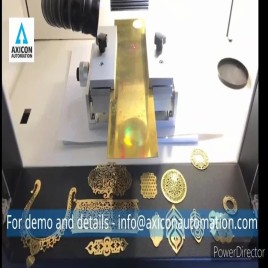

Jewellery Laser Welding Machine

Jewellery Spot Laser Welding Machine

Brand:

Others

Price ₹

3,85,000.00

| General Details: | |

| model | Jewellery Spot Laser Welding Machine |

| Material | GOLD & SILVER |

| Voltage | 220V |

| Frequency | 50HZ |

| Automation Grade | Semi-Automatic |

| Usage/Application | JEWELLERY WELDING |

| Others: | |

| Power Type | Electric |

Gold Welding Machine

Brand:

Others

Price ₹

4,55,000.00

| General Details: | |

| model | Gold Welding Machine |

| Material | METAL |

| Voltage | 220V |

| Frequency | 50HZ |

| Automation Grade | Semi-Automatic |

| Usage/Application | FOR JEWELLERY INDUSTRY |

| Others: | |

| Available | In Stock |

| Country of Origin | Made in India |

| Power Type | Electric |

| Business Type | Manufacturer, Supplier |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

Silver Welding Machine

Brand:

Others

Price ₹

4,85,000.00

| General Details: | |

| model | Silver Welding Machine |

| Material | METAL |

| Voltage | 220V |

| Frequency | 50HZ |

| Automation Grade | Semi-Automatic |

| Usage/Application | JEWELLERY WELDING |

| Others: | |

| Dimension | 900mm*540mm*1260mm (L*W*H) |

| Output Current | 220V |

| Power Type | Electric |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

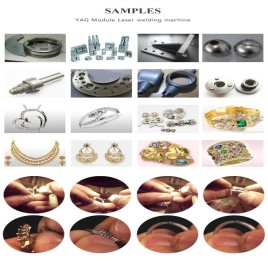

Jewellery Laser Welding Machine

Brand:

Others

Price ₹

3,79,000.00

| General Details: | |

| model | Jewellery Laser Welding Machine |

| Material | ALL METAL |

| Automation Grade | Automatic |

| Usage/Application | JEWELLERY WELDING |

| Others: | |

| Laser pulse width | 1064NM |

| Observing System | CCD VISION |

| Power Type | Electric |

| Power | 200W |

| SPOT DIAMETER | 0.02 MM |

| SPOT SETTING | ADJUSTABLE |

| Surface Finish | QUALITY |

Jewellery Soldering Machine

Brand:

Others

Price ₹

3,90,000.00

| General Details: | |

| model | Jewellery Soldering Machine |

| Material | METAL |

| Voltage | 220V |

| Frequency | 50HZ |

| Output Current | 220V |

| Automation Grade | Semi-Automatic |

| Usage/Application | JEWELLERY WELDING |

| Others: | |

| Automation Grade | Semi-Automatic |

| Capacity | 200W |

| Power | 200W |

GOLD & SILVER Electric Jewellery Spot Laser Welding Machine

Brand:

Others

Price ₹

3,85,000.00

| General Details: | |

| model | GOLD & SILVER Electric Jewellery Spot Laser Welding Machine |

| Material | GOLD & SILVER |

| Voltage | 220V |

| Frequency | 50HZ |

| Automation Grade | Semi-Automatic |

| Usage/Application | JEWELLERY WELDING |

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| Power | 200W |

| Power Type | Electric |

| Business Type | Manufacturer, Supplier |

| I Deal In | New Only |

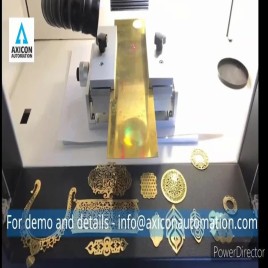

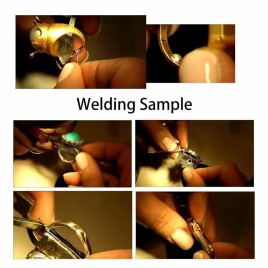

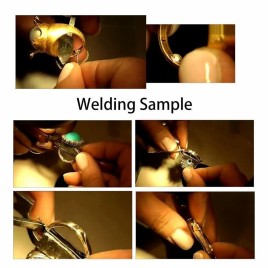

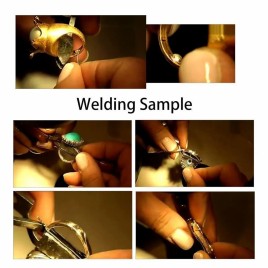

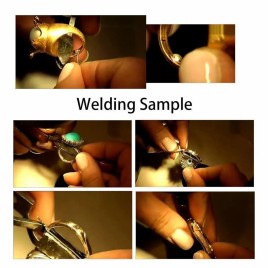

METAL Jewellery Soldering Machine, Capacity: 200W, Semi-Automatic

Brand:

Others

Price ₹

3,90,000.00

| General Details: | |

| Automation Grade | Semi-Automatic |

| Material | METAL |

| Frequency | 50HZ |

| Output Current | 220V |

| Usage/Application | JEWELLERY WELDING |

| Voltage | 220V |

| Others: | |

| Automatic Grade | Semi-Automatic |

| Availability | In Stock |

| Brand | AXICON |

| Capacity | 200W |

| Chamber Illuminations | LED |

| Cooling System | WATER COOLING |

| Country of Origin | Made in India |

| Dimension | 900mm*540mm*1260mm (L*W*H) |

| I Deal In | New Only |

| Language Display | ENGLISH |

| Laser Pulse Width | 0.1-20MS |

| Laser Source | ND:YAG |

| Observing System | Microscop |

| Parameters Memorization | UP TO 10 |

| Pilot laser | red |

| Power | 200W |

| Power Consumption | 4-6 KW |

| Power Supply | 220V+-10%/50Hz |

| Spot Size Adjustable | 0.2-3MM |

| Surface Finish | FINE |

| Weight | 130KGS |

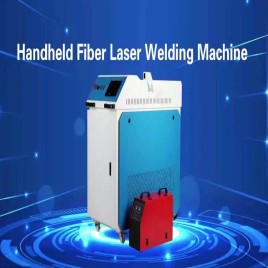

Jewellery Laser Welding Machine, Automation Grade: Automatic

Brand:

Others

Price ₹

4,79,000.00

| General Details: | |

| Automation Grade | Automatic |

| Material | ALL METAL |

| Usage/Application | JEWELLERY WELDING |

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| Current | 200 AMP |

| Laser pulse width | 1064NM |

| Model Name/Number | JEWELD200 |

| Observing System | CCD VISION |

| Power | 200W |

| Power Type | Electric |

| Single pulse energy | Jewellery Laser Welding Machine" |

| SPOT DIAMETER | 0.02 MM |

| SPOT SETTING | ADJUSTABLE |

Electric Jewellery Laser Soldering Machine, Power: 200W

Brand:

Others

Price ₹

3,40,000.00

| General Details: | |

| Automation Grade | Semi Automatic |

| Material | Gold & Silver |

| Frequency | 50 Hz |

| Output Current | 100A |

| Usage/Application | For Soldering Purpose |

| Voltage | 220V |

| Others: | |

| Availability | In Stock |

| Laser pulse width | 0.1 mm - 3.3 mm |

| Model Name/Number | JEWELD200 |

| Observing System | Microscope |

| Power | 200W |

| Power Type | Electric |

| Single pulse energy | 100 J |

| Spot Diameter | 0.1 mm - 3 mm |

Electric Gold Jewellery Laser Solder Machine, Power: 200W

Brand:

Others

Price ₹

4,55,000.00

| General Details: | |

| Automation Grade | Semi Automatic |

| Material | Gold & Silver |

| Frequency | 50 Hz |

| Output Current | 100A |

| Usage/Application | For Jewellery Industry |

| Voltage | 220V |

| Others: | |

| Availability | In Stock |

| Laser pulse width | 0.1 mm - 3.3 mm |

| Model Name/Number | JEWELD200 |

| Observing System | Microscope |

| Power | 200W |

| Power Type | Electric |

| Single pulse energy | 100 J |

| Spot Diameter | 0.1 mm - 3 mm |

METAL Electric Gold Welding Machine, FOR JEWELLERY INDUSTRY

Brand:

Others

Price ₹

3,55,000.00

| General Details: | |

| Automation Grade | Semi-Automatic |

| Material | METAL |

| Frequency | 50HZ |

| Usage/Application | FOR JEWELLERY INDUSTRY |

| Voltage | 220V |

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Power Type | Electric |

| Weight | 130KGS |

GOLD Electric Jewellery Laser Welding Machine

Brand:

Others

Price ₹

3,50,000.00

| General Details: | |

| Automation Grade | Semi-Automatic |

| Material | GOLD |

| Frequency | 50HZ |

| Usage/Application | FOR JEWELLERY INDUSTRY |

| Voltage | 220V |

| Others: | |

| Availability | In Stock |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Power | 200W |

| Power Type | Electric |

Electric Gold Soldering Machine, For JEWELLERY WELDING, Semi-Automatic

Brand:

Others

Price ₹

3,65,000.00

| General Details: | |

| Automation Grade | Semi-Automatic |

| Material | GOLD |

| Frequency | 50HZ |

| Output Current | 220V |

| Usage/Application | JEWELLERY WELDING |

| Voltage | 220V |

| Others: | |

| Automatic Grade | Semi-Automatic |

| Availability | In Stock |

| Brand | AXICON |

| Capacity | 200W |

| Country of Origin | Made in India |

| Power | 200W |

| Power Type | Electric |

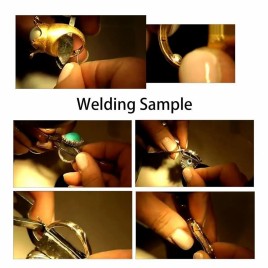

METAL Electric Silver Welding Machine, Capacity: 200W, Semi-Automatic

Brand:

Others

Price ₹

3,84,987.00

| General Details: | |

| Automation Grade | Semi-Automatic |

| Material | METAL |

| Frequency | 50HZ |

| Output Current | 220V |

| Usage/Application | JEWELLERY WELDING |

| Voltage | 220V |

| Others: | |

| Automatic Grade | Semi-Automatic |

| Availability | In Stock |

| Brand | AXICON |

| Capacity | 200W |

| Chamber Illuminations | LED |

| Cooling System | Water chiller |

| Country of Origin | Made in India |

| Dimension | 900mm*540mm*1260mm (L*W*H) |

| I Deal In | New Only |

| Language Display | English |

| Laser Pulse Width | 0.1-30 ms |

| Laser Source | NDYAG |

| Observing System | microscope |

| Parameters Memorization | up to 10 |

| Pilot laser | Red |

| Power | 200W |

| Power Consumption | less than 6kw |

| Power Supply | 220V AC |

| Power Type | Electric |

| Spot Size Adjustable | 0.1-3 mm |

| Surface Finish | FINE |

| Weight | 130KGS |

if you are interested, please fill the below details: