Gold Laser Cutting Machine

Jewellery Laser Cutting Machine

Brand:

Others

Price ₹

7,19,000.00

| General Details: | |

| Model | Jewellery Laser Cutting Machine |

| Power | 50w | 60w | 100w |

| Voltage | 230 v |

| Usage/Application | Effective solutions for producing precision cutting of precious metals,like Gold,Silver,Brass,SS |

| Others: | |

| Model Name/Number | Intelli JEWELMARK |

| Temperature | 27 C |

| Body | Enclosed MS Body Structure |

| Frequency | 50 - 500 khz |

| Gold Cutting | 28 - 30 gauge |

| Modal | Jewellry Laser Cutting Machine |

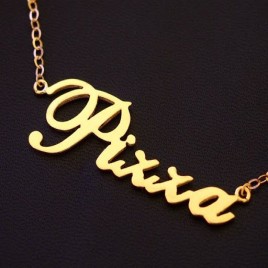

Jewelry Laser Cutting Machine

Brand:

Others

Price ₹

3,50,000.00

₹4,50,000.00

| General Details: | |

| Usage/Application | Used to Cut & Engrave Gold, Silver, Brass jewellery with Laser. |

| Material | GOLD, SILVER, BRASS |

| Voltage | 220V |

| Model | Jewelry Laser Cutting Machine |

| Automation Grade | SEMI AUTOMATIC |

| Others: | |

| Phase | 1 |

| Frequency | 20-80 |

| MADE IN | BHARAT |

| Output Current | 1 |

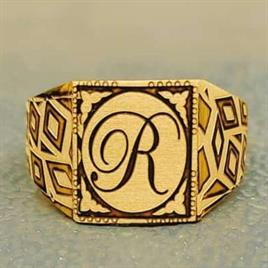

Gold Laser Cutting Machine

Brand:

Others

Price ₹

2,50,000.00

₹4,50,000.00

| General Details: | |

| Usage/Application | Used to Cut & Engrave Gold, Silver, Brass jewellery with Laser. |

| Material | GOLD, SILVER, BRASS |

| Voltage | 220V |

| Model | Gold Laser Cutting Machine |

| Automation Grade | SEMI AUTOMATIC |

| Others: | |

| Phase | 1 |

| Frequency | 20-80 |

| Output Current | 1 |

Jewelry Laser Cutting Machine

Brand:

Others

Price ₹

7,19,500.00

| General Details: | |

| Usage/Application | Effective solutions for producing precision cutting of precious metals,like Gold,Silver,Brass,SS |

| Voltage | 230 v |

| Power | 50w | 60w | 100w |

| Others: | |

| Frequency | 50 - 500 khz |

| Weight | 175 Kgs |

| Temperature | 27 C |

| Model Name/Number | Intelli JEWELMARK |

| Gold Cutting | 28 - 30 gauge |

| Country of Origin | Made in India |

| Brand | Axicon Automation |

| Body | Enclosed MS Body Structure |

| Availability | In Stock |

if you are interested, please fill the below details: